Shooting Heavy: The Ultimate Guide to 360° Video and Photos for Furniture & Appliances

In the world of e-commerce, the sneaker is easy. A running shoe weighs less than a pound. You can spin it on a lazy susan, a cheap plastic turntable, or even by hand if you are desperate.

But what happens when the client sends you a mechanical recliner chair, a refrigerator or a washing machine, or even a motorcycle engine?

Suddenly, the physics change. When you are asked to shoot 360° video or high-resolution photogrammetry / gaussian splats for heavy inventory, regular "consumer" gear doesn't just struggle—it fails.

If you have ever heard the sickening crunch of a plastic gear stripping mid-shoot, or watched your footage back only to see a jittery, unusable wobble, this guide is for you. Here is why shooting heavy requires a fundamental shift in your hardware strategy.

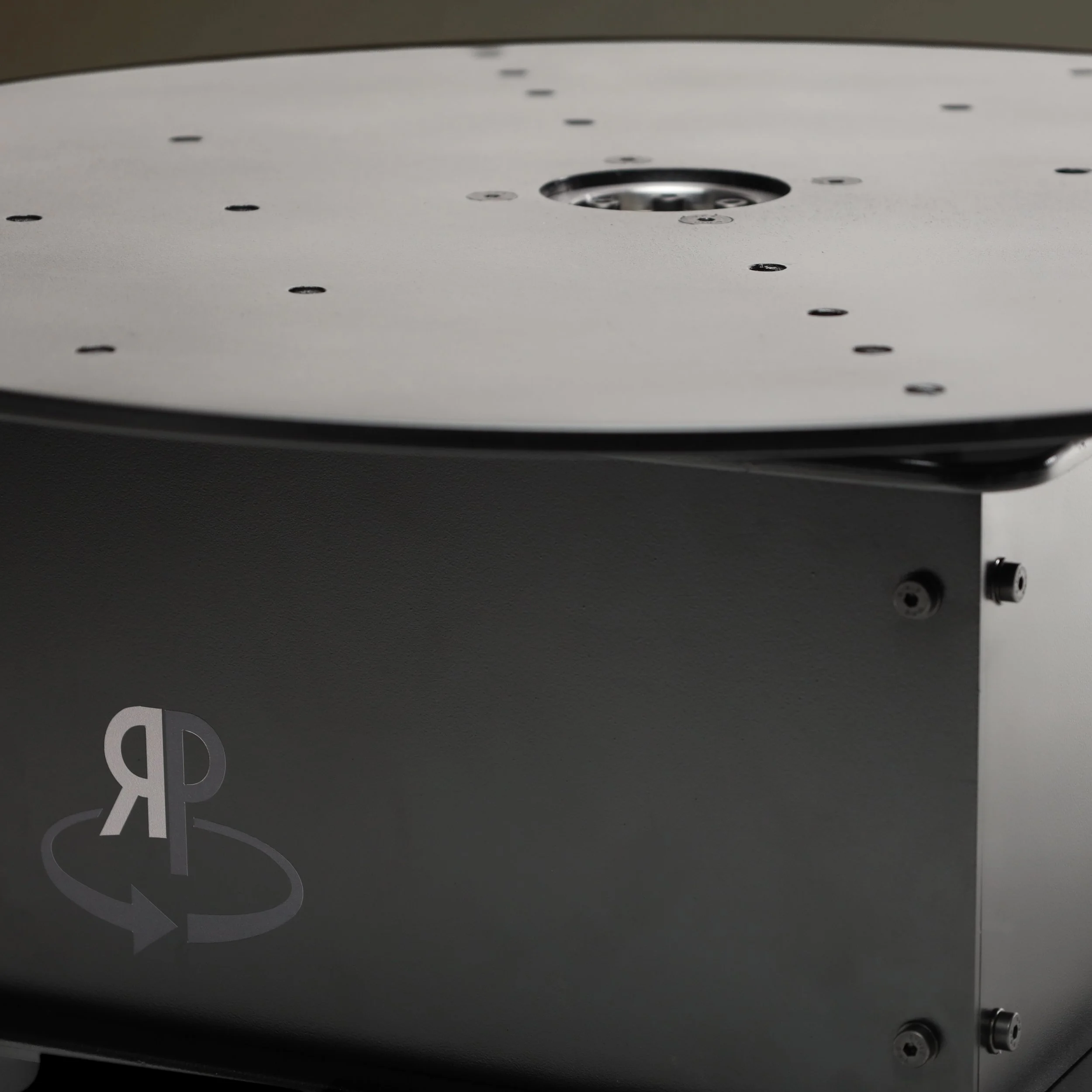

Precision under pressure: The Revo Continental handling a 300lb load.

The Physics of Failure: Why Standard Turntables Can't Keep Up

To understand why most turntables fail, you have to look at torque and inertia.

A heavy ( in this case 300 lbs) object wants to stay still. To get it moving, a motor needs a massive amount of low-end torque. Cheap turntables typically use small motors connected to plastic gears. When they try to push that much weight, two things happens:

The Gears Strip: The motor spins, but the teeth shear off the plastic cog.

The "Micro-Jitter" Problem

Even if a cheap unit manages to get the object moving, it rarely keeps it moving smoothly. In still photography, you might not notice a tiny variation in speed. But in 360° video, consistency is everything.

A struggling motor creates "micro-jitters"—tiny accelerations and decelerations as the motor fights the weight. On camera, this looks like the video is vibrating. It ruins the premium feel of the product and often makes the footage unusable for broadcast or high-end web use.

The Industrial Solution: Engineering for up to a 400 lb Payload

At Revo North America, we don't believe in plastic gears. We believe in Milwaukee metal.

We engineered the Revo Continental specifically to solve the "Heavy Weight" problem. We approached the design not as a camera accessory, but as industrial machinery.

Machined, not stamped: The Continental chassis is machined using 6061 aircraft-grade aluminum. Mass absorbs vibration. By starting with a heavy, rigid foundation, we ensure that the turntable remains rock-solid even when the payload shifts.

Smooth Belt Drive Authority:. The Continental uses a high-torque drive system capable of handling up to 400 lbs (180 kg).

Near Zero Backlash Precision: Whether you are shooting a continuous video loop or indexed stop-motion frames, the movement is exact. When you tell it to stop, it stops. When you tell it to move, it moves. No drift. No bounce.

Caption: Built in Milwaukee with attention to detail.

Best Practices for Shooting Heavy Objects

Having the right tool is step one. Using it correctly is step two. When you are moving hundreds of pounds on set, physics still applies.

1. Center Your Mass (The "Wobble" Factor)

A turntable motor can handle weight, but it hates eccentric loads. If you place a 300 lb sofa six inches off-center, you create a lever arm that fights the motor on every rotation.

Pro Tip: Use the grid of tapped holes on the Continental’s surface to create repeatable alignment jigs. Take the time to find the true center of gravity of your object before you hit record.

2. Use Ramping for Video

Inertia works both ways—it’s hard to start moving, and hard to stop. If you jolt a heavy object into motion instantly, the product itself might shift or vibrate.

The Fix: Use our Transmogrifier interface to connect the Continental to Dragonframe. Inside the software, you can program a gentle "Ramp Up" and "Ramp Down" (acceleration/deceleration) curve. This eases the heavy object into motion, ensuring the product stays perfectly still relative to the platter.

3. Secure the Load

For tall, heavy items (like a refrigerator), top-heaviness is a risk.

Safety First: The Continental’s aluminum platter allows you to mechanically fasten (if needed) items down using standard 1/4"-20 or 3/8"-16 bolts. Don't rely on gravity alone if the object is tall and narrow.

Investing in Reliability

In the high-pressure environment of a commercial studio, the most expensive piece of equipment you own is the one that breaks in the middle of a shoot. When you are on set with a client, and a heavy product causes your plastic turntable to fail, you aren't just losing a piece of gear—you are losing your reputation.

We built the Continental to be a "forever tool." It mirrors the philosophy of functional honesty and the Milwaukee tradition of heavy manufacturing.

Don’t let "good enough" gear limit what you can say "yes" to. If your clients are bringing you the heavyweights, you need a turntable that can spot them.

Ready to upgrade your studio's capabilities?

Discover the Revo Continental and give your heaviest products the stage they deserve.